Gasoline Direct Injection Engines Explained

This article is about gasoline direct injection (GDI) and everything you need to know about GDI engines.

You will learn:

-

How GDI works and how it differs from indirect injection (port injection)

-

GDI emissions – the elephant in the room

-

Advantages and disadvantages of gasoline direct injection

-

The problem of carbon build-up in direct injection engines

-

Practical things that you can do to prevent carbon build-up in your car

-

What walnuts have to do with GDI engines

But first, here’s a short history lesson.

Direct fuel injection is a very old idea

Until the early 2000s, direct injection was mainly associated with diesel engines. However, gasoline direct injection isn’t a new idea.

The first engine to use direct injection was a V8 aircraft engine created by Leon Levavasseur in 1902 – a hundred years before GDI became widely used in passenger cars.

Going forward, the first mass-produced gasoline direct injection engine was the DB 601 A. Its origins are unfortunate as it was developed by Daimler-Benz just before World War II and fitted to various Messerschmitt aircraft, later used to bomb half of Europe.

Daimler-Benz remained the pioneer of direct injection engines and released the world’s first production car with a four-stroke, gasoline direct injection engine in 1954. It was the famous Mercedes-Benz 300 SL with its three-litre, straight six engine developing 243 PS (179 kW).

All the engines mentioned above used mechanical direct injection, which never became popular in mass-produced cars because of its complexity and problems with engine oil getting diluted with unburnt fuel. Without precise electronic fuel metering systems that we have today, it was very difficult to tune DI engines and keep them running reliably.

Daimler benz shyed away from direct injection in favour of manifold fuel injection, which was less sensitive to fuel injection timing and more reliable. And so, indirect fuel injection and carburettors remained the standard solutions for the next 50 years.

The first indirect fuel injection systems were mostly mechanical and eventually evolved into electronic fuel injection (EFI) that we know today.

In 1996, gasoline direct injection made a comeback with the appearance of Mitsubishi’s GDI engines. Other manufacturers soon followed the emerging trend. Fast forward to today, the majority of all new gasoline engines use direct injection.

The old problems of controlling injection pump timing are gone thanks to the lightning-fast, electrically-controlled fuel injectors and powerful electronic control units (ECU). The history of the gasoline engine started with direct fuel injection, and it will potentially end with direct fuel injection (if electric cars ever take over).

Comparison of fuel injection systems

Before I start explaining how direct injection works and its modes of operation, let’s compare these three injection systems:

-

Gasoline Direct Injection (GDI)

-

Port Fuel Injection (PFI)

-

Common Rail (CR)

The reason why common rail (diesel cars) is on this list is because it’s very similar to the injection system used in GDI engines.

Gasoline Direct Injection vs Common Rail

Here’s how these two injection systems are similar:

There are two fuel pumps. A low-pressure pump is located in or near the fuel tank. It feeds the fuel to the high-pressure pump located in the engine bay. The high-pressure pump is driven mechanically by the engine, while the low-pressure pump is electric.

From the high-pressure pump, the fuel is fed to the fuel rail, aka the “common rail”, at high pressure.

The fuel rail is connected to the fuel injectors that spray fuel directly into the combustion chamber. The fuel injectors are electrically controlled (solenoid or piezoelectric injectors) and can fire at any time – the injection timing is determined by a set of electronic sensors.

The injectors can fire multiple times per combustion cycle, and engine operation at lean air-fuel ratios is possible.

The above description fits both GDI and common rail diesel engines.

They aren’t identical though, and here’s what the main differences between them are:

First, the injection pressures are much lower in direct injection gasoline cars. Modern diesel injectors operate at 2,500 bar (36,000 psi), while gasoline direct injection runs at around 200 bar (2,900 psi).

For those of you that don’t know what one “bar” is – it is roughly the same as the atmospheric pressure, so 2,500 bar is 2,500 times higher than the atmospheric pressure, which is a lot of pressure.

Gasoline is a far worse lubricant than diesel fuel, so the injection pressures have to be lower. Still, even 200 bar (2,900 psi) already requires some good engineering to make the system run reliably without wearing out the injectors from pumping a solvent (gasoline).

The second difference between common rail and GDI is that a high-pressure diesel pump is driven by the timing belt or the timing chain, while a high-pressure gasoline pump is driven directly off the camshaft by an extra cam.

Both systems use piston pumps, and the difference between them is that the common rail pump has its own internal camshaft (with usually a single cam lobe). The end result is the same for both systems – a cam moves the pump pistons (called high-pressure elements) to generate the required pressure.

The GDI pump does not require as much power (lower pressure & a single high-pressure element) as a common rail pump, so it’s possible to eliminate the extra camshaft inside the pump and just add an extra cam to the engine’s camshaft.

To grossly oversimplify things: GDI is Common Rail technology for gasoline engines.

Makes sense so far?

We are now done with diesel engines and let’s focus on gasoline engines, which is what this article is about after all. If you’d like to learn more about the good and bad things about Common Rail diesel cars – please follow this link.

Gasoline Direct Injection vs Port Injection

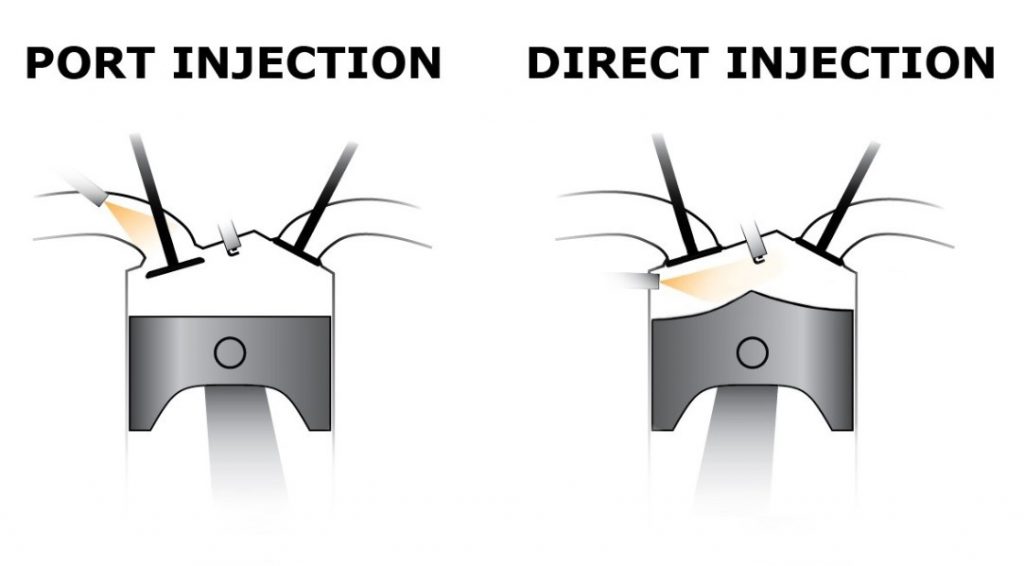

The key difference between these two systems is the location of the fuel injectors (duh!).

In port-injected engines, the fuel is delivered into the intake manifold, very close to the intake port and the valves. The injected fuel mist washes over the intake valves as it enters the combustion chamber. The injectors fire only once per combustion cycle.

In GDI engines, the injectors deliver fuel directly into the combustion chamber. This allows for new lean burn injection strategies, which I will explain in a moment.

Here’s a summary of other important differences between GDI and PFI engines:

-

GDI engines have two fuel pumps and injection pressure up to 200 bar (2,900 psi). PFI engines need only around 4 bar (70 psi). That’s why a single electric fuel pump is enough.

-

The air-fuel mixture is prepared mostly outside of the cylinders in PFI engines. In GDI engines, the air-fuel mixture is prepared fully inside the cylinders.

-

The fuel droplets in the injected fuel spray need to 5-10 times smaller in GDI engines in order for the fuel to mix with the air in a much shorter period of time.

-

GDI engines require much finer injection control (fast injectors, more powerful ECU, correct spray pattern) due to a significantly tighter time window to deliver fuel and more sophisticated injection strategies.

-

PFI engines operate at close to stoichiometric air/fuel ratios (14.7:1), while GDI engines can run on a very lean A/F mixture (up to 50:1) in some modes of operation.

-

GDI injectors are exposed to the combustion process. It is a new engineering problem to solve. Otherwise, the injector lifespan will suffer. At high pressures that GDI engines operate at, low fuel lubricity is also an issue.

-

Moving the injector to the combustion chamber means that the intake valve cleaning effect has been lost, which makes GDI engines susceptible to carbon build-up on the intake valves.

How gasoline direct injection engines work

Before I explain how direct injection engines work, the main thing to remember about them is that a portion of the injected fuel spray must be directed towards the spark plug.

This enables new injection strategies that were not possible in port-injected engines, which is what all the fuss with GDI engines is about.

There are three ways of guiding the fuel inside the engine cylinders:

-

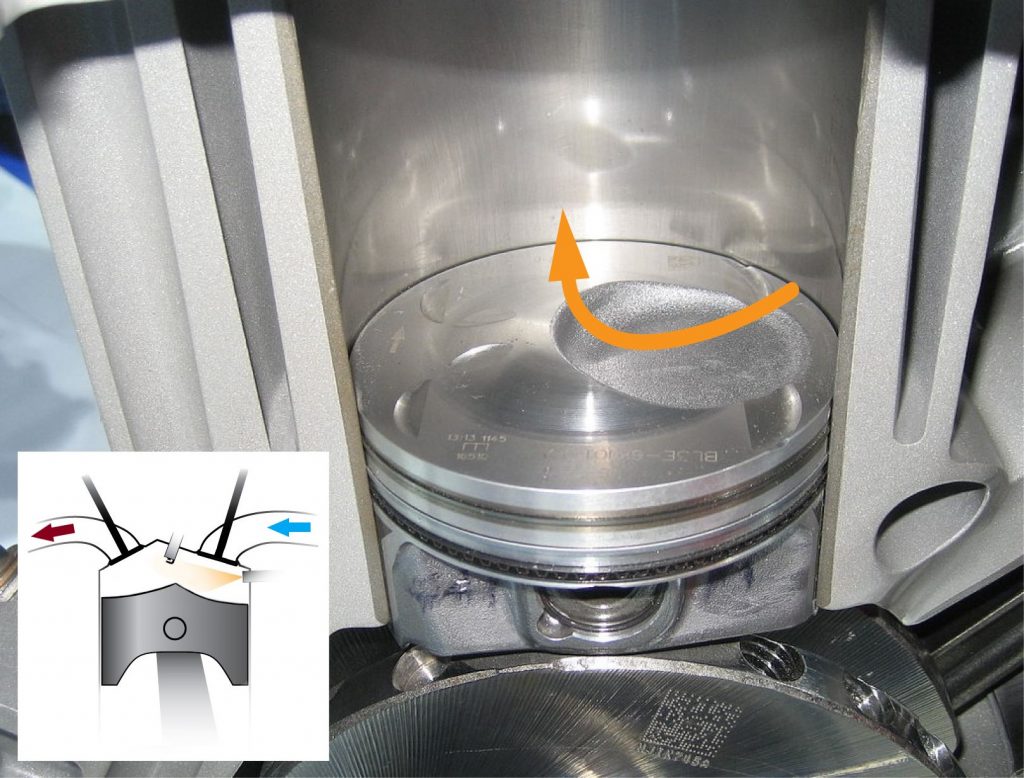

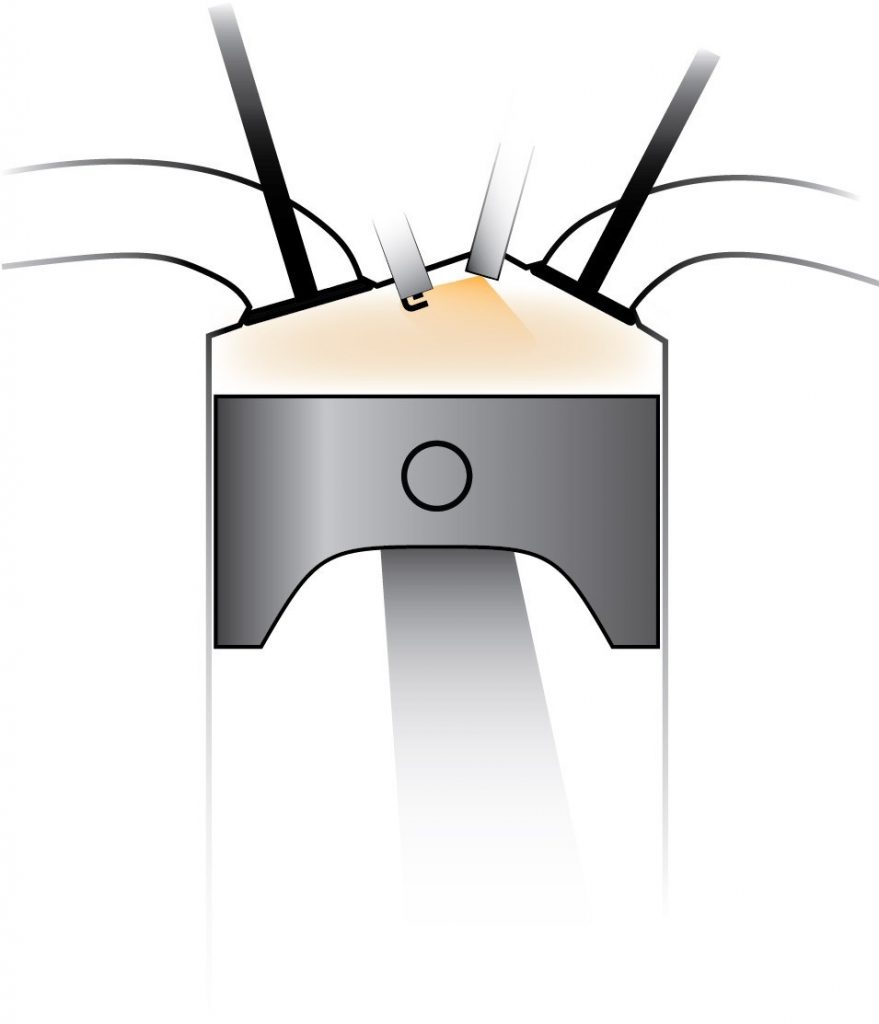

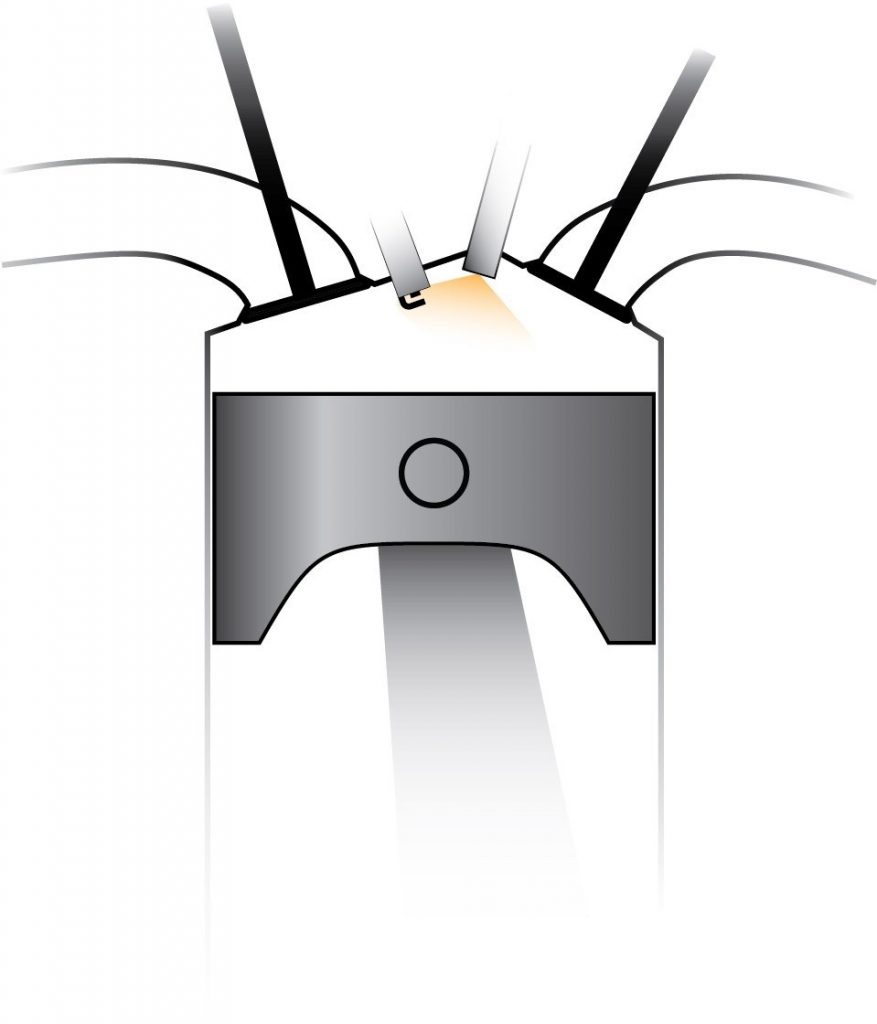

Wall-guided injection – using the geometry of the piston crown to direct the fuel spray towards the spark plug (requires a specially shaped piston crown) – see image below

-

Spray-guided injection – spraying a cone of fuel from the top of the cylinder towards the piston (requires the spark plug to be in the injector spray pattern and usually a cavity in the piston crown)

-

Air-guided injection – relying on the airflow to move the fuel spray near the spark plug (requires specially shaped intake ports)

GDI modes of operation

Okay, we can finally get the key advantage of GDI engines, which is its ability to operate at lean air-fuel ratios.

There are 3 basic modes of GDI engine operation. The car’s ECU switches between them depending on the engine RPM and engine load.

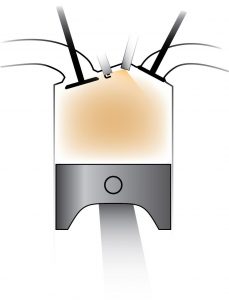

1. Homogeneous Charge – high RPM or high engine load

In this mode, the cylinder “charge” is a uniform mixture of air and fuel at ratios close to stoichiometric (14.7:1). At full engine load, the mixture becomes slightly rich to generate the most power – just like in port-injected engines.

The “Homogeneous Charge” (uniform air-fuel mixture) is obtained by injecting fuel at the beginning of the intake phase. This single early injection provides all the fuel required for combustion. Because the injection happens early, there is plenty of time for the air to mix with the fuel inside the cylinders to create a homogeneous mixture.

GDI engines typically run in Homogeneous Charge mode in the upper part of the rev range and at full throttle. What’s important here is that GDI engines are only slightly more efficient than port-injected engines at full throttle.

The full benefit of direct injection is not achieved in Homogeneous Charge mode, and the slightly higher efficiency comes from higher compression and a more precise fuel injection system.

GDI engines can have higher compression ratios, which directly improves efficiency, due to the charge cooling effect of the injected fuel evaporating inside the cylinders. Let me explain this a bit better.

According to the laws of physics, an evaporating liquid cools the object that it comes in contact with. That’s why you feel colder when you’re wet – the evaporating water takes the heat away from your body.

This cooling effect inside the cylinders provides better resistance to knocking, which means that GDI engines can have higher compression ratios.

Port injected engines don’t benefit from the charge cooling effect as much because the fuel already starts evaporating inside the manifold (cooling the manifold is nice but not as good as cooling inside the cylinders).

Due to better fuel atomization, precise fuel delivery and higher compression, a typical GDI engine can be roughly 5% more efficient than a comparable PFI engine when operating in Homogeneous Charge mode. In other words, you can still enjoy a 5% improvement in fuel economy when you drive with the pedal to the metal.

2. Homogeneous Stratified Charge – low/medium RPM and medium engine load

This mode of operation is a transition phase between Stratified Charge operation and Homogeneous Charge operation.

In this mode, the fuel injectors fire twice before each combustion event. The first dose of fuel is delivered early during the intake stroke – just like in Homogeneous Charge mode. The difference here is that this first shot of fuel is smaller and it creates a lean air-fuel mixture inside the cylinder.

The second shot of fuel is delivered just before combustion, which creates a pocket of richer air-fuel mixture around the spark plug. The spark plug can easily ignite the richer mixture, which initiates the combustion of the entire cylinder charge. This is why I emphasized earlier that a portion of the injected fuel must be directed at the spark plug.

The term “Homogeneous Stratified Charge” is related to the cylinder charge (air/ fuel mixture). A lean, homogeneous air-fuel mixture is created inside the cylinder, then the fuel injector “stratifies” the charge by creating regions with different air-fuel ratios.

Homogeneous Stratified Charge mode enables the engine to run on a lean air/fuel mixture.

3. Stratified Charge – low/medium RPM and low engine load

Stratified Charge mode enables the engine to run on a very lean air/fuel mixture (even 50:1). In this mode, the early fuel injection is skipped entirely. Instead, the fuel injector fires just before combustion. There is very little fuel injected, so it must be directed at the spark plug to ensure stable ignition.

This is where the magic happens. A GDI engine running in Stratified Charge mode can be up to 20% more efficient than a comparable PFI engine. As you can see, there’s more to GDI than just moving the injectors from the manifold to the cylinders.

Stratified Charge mode has a certain resemblance to how diesel engines operate – a very lean mixture that combusts soon after the fuel is injected and a fully open throttle plate (this is important – I’ll explain in a moment).

Unfortunately, Stratified Charge operation is only possible at low engine loads in most engines today. The key for car manufacturers is now to increase the amount of time engines spend in lean burning modes.

As a driver, you can improve your fuel by driving gently. At low engine loads, GDI engines switch to Stratified Charge mode and run more efficiently, for example, during cruising at low/medium speeds.

Based on this logic, larger engines will stay in Stratified Charge mode more often because they are less stressed.

Therefore, bigger engines burn less fuel!

Wait… Is that right?

Throttling losses in GDI engines

The modes of operation described above aren’t the only ones. At the time this article was written, Bosch injection systems could operate in six modes. However, all other modes of operation derive from the three I described above. If you understand the ones I outlined, we can continue.

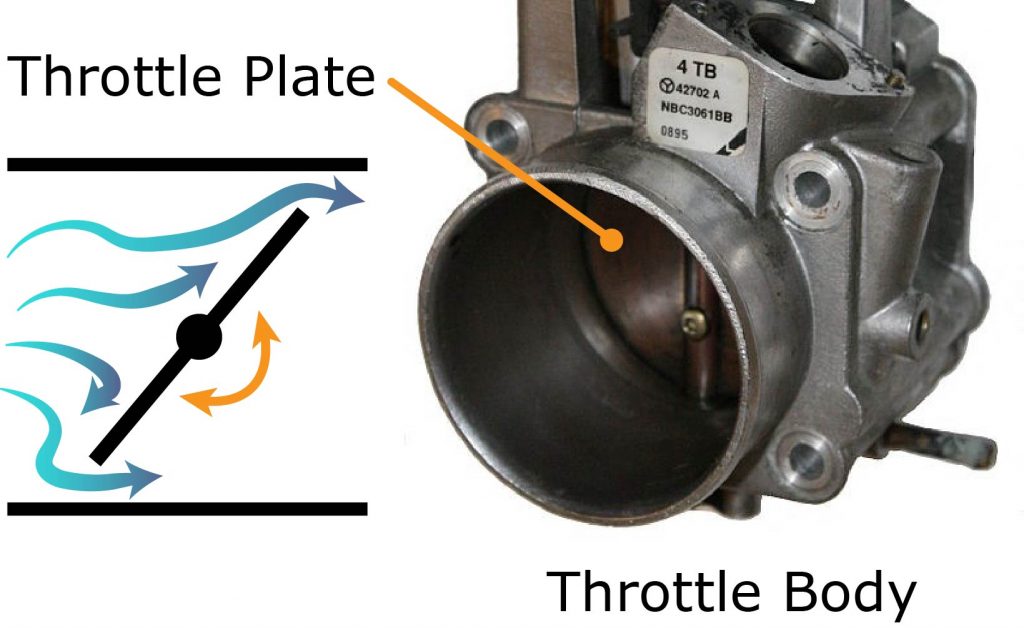

So, I’ve explained the strategies GDI engines use to achieve higher efficiency, but I haven’t explained why lean air/fuel mixture is good for engine efficiency. Why not simply close the throttle plate to reduce the amount of air entering the engine so less fuel is needed to maintain a stoichiometric air/fuel ratio?

Indeed, this is how port-injected engines operate. The problem with a partially closed throttle plate is that it restricts airflow. This creates a vacuum in the intake manifold because the engine is trying to suck in more air than it is allowed to, which wastes energy. Imagine trying to breathe through a straw.

A partially closed throttle plate reduces efficiency due to increased pumping loses. These losses are called throttling losses.

Unthrottled operation in gasoline engines (fully open throttle plate) has been engine designers’ wet dream for quite a while. GDI finally made it possible. When running in Stratified Charge mode, the throttle plate can remain open.

Out of all the factors that improve GDI engine efficiency, reducing throttling loses is the largest contributor – more important than the higher compression ratio or more precise fuel delivery. This is what GDI is all about – running the engine lean to keep the throttle plate open.

Depending on how you drive, you can expect a 7-15% real-world improvement in fuel economy from a GDI engine as compared to a similar PFI engine. I’m sure this number will still improve slightly as engineers find ways to make GDI engines spend more time in lean-burning modes.

By the way, diesel engines don’t need throttle bodies at all (although many have them as they can be used to improve emissions).

The elephant in the room – GDI engine emissions

We will now look at GDI emissions – specifically the CO2, nitrogen oxides, and particulate matter.

The level of CO2 emissions is directly linked to the amount of fuel consumed by the engine. GDI engines are more efficient, therefore, they emit less CO2, which is great. When it comes to CO2, GDI engines are definitely better than PFI engines.

When operating at air-fuel ratios close to stoichiometric, the emissions in GDI engines are similar to those in PFI engines. However, when operating in lean-burning modes, the emissions change and become more diesel-like.

When operating in Stratified Charge mode, the combustion takes place soon after the fuel is injected. Therefore, the fuel doesn’t have much time to mix with the air, which results in areas of high fuel concentration that don’t burn cleanly and are a source of particulate matter.

Wall-guided GDI engines emit the most particles due to some of the fuel remaining on the piston crown rather than mixing with the air charge (fuel impingement).

Therefore, GDI engine emissions contain a lot more particulate matter as compared to PFI engines. You thought you can have your cake and eat it too?

Along with the increase in particle emissions, GDI engines also used to emit more nitrogen oxides (NOx). However, NOx emissions is not an issue at the moment as there are effective strategies that manufacturers have successfully employed. The latest GDI engines have NOx emissions that are comparable to those from PFI engines.

On the other hand, higher particulate emission is a real problem with GDI engines. Particulate matter is what got older diesel cars banned from city centres all over the world. Particulate matter is one of the main ingredients of smog and ultrafine particles can give you lung disease and cancer.

Can you see the plot twist coming?

Gasoline engines used to have very low emissions of particulate matter due to burning a uniform and stoichiometric air/fuel mixture resulting in clean combustion. In a GDI engine, you can have a rich and lean condition at the same time (not uniform and not stoichiometric).

While the legislators were focused on “dirty” diesel engines and their impact on the environment, there were no emission standards for particulate matter (PM) for gasoline engines until Euro 5 in 2009 and no limit for ultrafine particles (PN) until Euro 6b in 2014.

What does it mean?

It means that pre-2009 GDI engines were designed primarily to lower CO2 emissions, with little regard to particle emissions. It took a decade to bring particulate emissions of cars with GDI engines down to the same level as…

…diesel cars.

Surprised? Let me explain then.

Below is a summary of what happened regarding particulate matter emissions in GDI engines based on European emission standards (which are similar for the rest of the world).

Before 2009: “Free-for-all”

No regulations for particulate matter mass (PM) or particle count (PN) meant that GDI engines from those years emit more particulate matter than diesel engines equipped with particulate filters.

Basically, the first generation of GDI engines was in the same league as diesel engines when it comes to particulate emissions.

This shouldn’t be surprising. Why would car manufacturers care about something that’s not measured or regulated?

2009-2014: “Keep calm and diesel on”

Between 2009 and 2014, the particulate matter emission limit (PM) for GDI engines was set at the same level as for diesel cars when Euro 5 came into force.

Still, there was no limit on the number of particles (PN) for cars with GDI engines in those years. The PN emission standard controls the number of ultrafine particles that are harmful to humans.

Since all diesel cars had to be fitted with particulate filters after 2009, GDI engines continued to emit a lot more ultrafine particles, which still weren’t regulated.

2014-2017: “Close, but no cigar”

Euro 6b finally established a limit on the number of particles (PN) for cars with GDI engines in 2014.

Still, that limit was 10 times higher than the limit diesel engines had to adhere to since Euro 5b. There goes nearly a decade of diesel engines still being cleaner than GDI engines when it comes to PN emissions. Funny, isn’t it?

After 2017: “Make gasoline engines clean again”

With the Euro 6c in 2017, the particulate emissions (both PM & PN) of GDI cars have finally been brought in line with diesel cars, which marks the beginning of GDI cars with gasoline particulate filters (not all cars though).

This latest generation of GDI engines is finally comparable to PFI engines when it comes to particulate matter emissions (still 25-100% more PM emissions when not equipped with a GPF).

Gasoline Particulate Filters (GPF)

I focused on high particulate matter emissions in the previous paragraph, but please remember that engineering is the art of compromise. While GDI engines struggled to meet PM and PN limits, they are quite good when it comes to CO2 emissions and they offer better fuel economy.

So, as of 2017 many gasoline engines have been fitted with gasoline particulate filters (GPF), which are based on the same principle as diesel particulate filters (DPF). Follow this link to read more about particulate filters and diesel cars in general.

For those of you who had bad experiences with diesel particulate filters, gasoline particulate filters should be less of a nuisance because they operate at higher temperatures and they have to filter less soot. This means that these filters may be able to regenerate passively without the need for active regeneration cycles (or at least less frequently).

China and Australia followed a similar pattern of regulations and their latest emission standards are based on European regulations.

The USA and Canada, on the other hand, do not regulate particulate matter emissions based on particle number (PN), so American and Canadian cars are unlikely to need gasoline particulate filters for now.

You can read more about worldwide emission standards here, you masochist.

As far as PFI engines are concerned – it’s unlikely that they will ever need particulate filters. The PM and PN emission limits mentioned above apply only to GDI engines. For now, cars with PFI engines will remain on the market and be used in smaller cars (where it’s easier to pass CO2 emission tests).

Carbon build-up on the intake valves

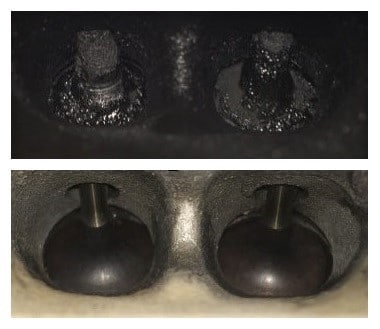

Carbon build-up is a common problem that affected early GDI engines as the fuel is no longer injected into the intake manifold where it has a chance to wash away any carbon build-up from the intake valves.

The carbon deposits come from the Crankcase Ventilation System (CVS), which is connected to the intake. In any piston engine, a small portion of the gases from the combustion chamber is blown past the piston rings into the crankcase.

From the crankcase, they are fed back into the engine cylinders through the intake manifold. These gases contain oil vapour (hydrocarbons) and combustion by-products (more carbon).

The second source of intake valve deposits is the Exhaust Gas Recirculation (EGR) system that redirects a portion of exhaust gases back into the engine intake (even more carbon).

Car manufacturers have been aware of this problem for quite some time and they’ve done a reasonably good job preventing carbon build-up in recent cars by optimizing the EGR and PCV systems. Engine oil formulas have also been improved and some cars even use dual-injection.

Sooner or later though, all GDI engines will have some carbon build-up on the intake valves. It is inevitable, Mr Anderson.

All the engineering workarounds only reduce the speed of deposit accumulation. The question is when or if it becomes a problem. Some engines will require the carbon to be cleaned up for the first time at 50,000 miles, which was not uncommon for the first generation of GDI engines, while others will need it at 200,000 miles.

While the latest GDI engines have been optimized to reduce the likelihood of carbon build-up being a problem, carbon build-up is something to consider when buying an older car with a GDI engine or a high-mileage one.

The symptoms of carbon build-up on the intake valves are as follows:

-

Reduced power and reduced fuel economy

-

Misfires

-

Rough idle (more common when cold)

-

Engine starting problems

-

Illuminated “Check Engine” light

The first symptom is usually loss of power, which often goes unnoticed because it’s a slow process. As the carbon builds up on the intake valves, the airways narrow and reduces the amount of air entering the engine (kind of like asthma).

There have been cases of cars losing 10% of power before other symptoms appeared or a fault was picked up by the engine management system. As intake valves get clogged up further, the car may start misfiring or running roughly when cold.

Dual injection systems

The only solution that completely eliminates carbon build-up is a dual fuel injection system.

Dual injection is a combination of GDI and PFI. This means that there are two injectors per cylinder – one in the combustion chamber (direct injection) and one in the intake manifold (port injection).

Some manufacturers (Toyota, Volkswagen, Ford) opted to go this route instead of trying to reduce the occurrence of carbon build-up with GDI alone.

Dual injection also has another benefit. Direct injection isn’t always better than port injection. For example, port injection is better than GDI in high load situations at low engine RPM.

At high loads and low RPM, there is a large demand for fuel but the low RPM means that the flow of air into the engine has a low velocity, therefore, it doesn’t mix with the fuel as well as at higher engine revs. With PFI, the air-fuel mixture starts being prepared already in the intake manifold (more time to create a uniform air-fuel mixture = better emissions).

Being able to use both GDI and PFI can improve emissions and engine efficiency:

-

At high RPM and high loads, the charge cooling effect of GDI is very useful to prevent knocking

-

At low RPM and high loads, PFI gives more time to prepare a homogeneous mixture, which is good for emissions and efficiency

The direct injectors are never completely disabled. They need to keep delivering some fuel to stay cool.

The only problem with dual injection is that it increases the cost and adds even more complexity to the car. What happened to the KISS Principle?

Carbon cleaning (and walnuts)

In response to the increasing number of direct injection cars and the increased number of cars with excessive carbon build-up, companies started offering carbon cleaning services.

There are 3 ways of cleaning the intake valves in a GDI engine and 2 of them work.

1. Manual valve cleaning

The intake manifold is removed, and the valves are cleaned one by one using some solvent and a metal brush. The valves need to be in a closed position to keep all the dirt from getting into the cylinders.

The sludge is then cleaned up, and the intake manifold is reattached. The cost of this procedure depends on the number of valves to clean and the labour required to remove and reinstall the intake manifold. It is quite labour intensive.

2. Walnut shell blasting

It’s a more sophisticated method of cleaning the intake valves. It’s like sandblasting, but gentler. Apparently, crushed walnut shells are an excellent media to blast at the engine valves without damaging them.

Like with manual valve cleaning, the intake manifold needs to be removed, but the cleaning procedure itself is quick and effective. The walnut shell media is blasted into the intake ports while simultaneously vacuuming the shells and the removed carbon.

3. HHO carbon cleaning

It’s cheap, quick, effortless and most likely won’t do much to clean coked-up valves. At least it wouldn’t for me – placebo works only when you believe in it.

The idea behind HHO carbon cleaning is that feeding a small amount of hydrogen and oxygen into the engine through the intake manifold increases the combustion temperature and burns away carbon deposits. The problem is that the intake valves are before the combustion chamber (low temperature, no combustion, no chemical reactions).

How to prevent carbon build-up on the intake valves

Detergent fuel additives don’t work in the GDI engines as the injected fuel doesn’t go over the intake valves like in manifold fuel injection systems. Therefore, it doesn’t have a chance to wash away the carbon deposits. So, don’t waste your money on fuel additives.

Here are 5 things you can do to help prevent excessive carbon build-up in your car:

1. Use engine oils that have low Noack volatility

The Noack volatility rating determines how quickly the oil evaporates at high temperatures. Lower evaporation means that less engine oil will travel to the intake valves through the positive crankcase ventilation system (PCV).

Use engine oils that have a Noack volatility below 10%. The lower the number, the better. However, not all manufacturers provide this information in their product information sheets.

So, if you don’t want to trawl through technical data, simply choose a high-quality, full synthetic oil that was designed with GDI in mind. Also, avoid the thinnest grades – the thicker the oil, the lower the Noack volatility.

If you want the best, these engine oils have some of the best Noack volatility ratings:

There’s also another good reason to use good quality engines oils in your GDI car and that’s oil dilution. GDI engines tend to have a higher level of oil dilution as some of the fuel that’s sprayed inside the cylinders gets on the cylinder walls and mixes with the engine oil.

One of the reasons why the internal parts of a diesel engine last longer is because diesel fuel is a better lubricant that doesn’t interfere with the oil film as much as gasoline. Gasoline, on the other hand, is a better solvent.

Gasoline engines have always been at a disadvantage and the switch from PFI to GDI will only make this effect more pronounced.

2. Install an oil separator

Installing an oil separator, commonly called a catch can, removes the oil vapours from the gases that travel from the crankcase into the intake manifold through the PCV system.

An oil separator needs to be emptied once in a while (typically every 3,000 or 5,000 miles) so it’s not an option that car manufacturers ever consider. However, it is an effective solution for engines that breathe in a lot of oil due to poorly designed PCV systems or have a lot of blow-by.

The more oil the engines consumes, the more effective the catch can will be.

3. Use a product designed to clean carbon build-up

CRC makes a product specifically for this purpose. You can get it here. Use it once a year as part of preventative maintenance.

Keep in mind that this is not for cars that already have a bad case of carbon build-up. A small can of solvent is unlikely to make a dent in years worth of carbon deposits. And if it does, that’s not good either, because any larger pieces of carbon that come off the intake valves will end up in the catalytic converter.

Manual valve cleaning is the correct solution for cars that are already running poorly due to carbon build-up.

4. Don’t drive like a granny

At high engine revs, the increased airflow and the rotation of the valves reduces the rate of deposit accumulation. In case you didn’t know, valves start rotating at higher engine revs, which keeps the valve seats clear from deposits and the valves from sticking.

So, let the engine rev above 3500 RPM regularly. This isn’t going to remove the accumulated carbon, but it will ensure that the valves are free and that they seal well.

5. Reduce engine oil consumption

Make sure that the valve stem seals and turbocharger seals in your engine are in good condition. Worn-out valve stem seals and a failing turbocharger compressor seal will contribute to carbon build-up by delivering more oil to the intake valves.

In other words, fixing the oil consumption will slow down the accumulation of carbon build-up on the intake valves.

Excessive blow-by that overpowers the filtering capabilities of the PCV system can also contribute to carbon build-up on the intake valves. However, if you have excessive blow-by, you have bigger concerns than carbon build-up…

Advantages of GDI engines

Here’s a summary of advantages that gasoline direct injection engines have over port-injected engines:

-

Higher efficiency – typically, 7-15% higher than PFI engines in the real world with the biggest difference at low engine loads

-

Higher specific power – more power and torque from the same engine displacement

-

Lower CO2 emissions

Disadvantages of GDI engines

Here’s a summary of disadvantages of gasoline direct injection engines when compared to port-injected engines:

-

Higher cost and complexity – GDI requires an extra fuel pump, sophisticated injectors and a more powerful ECU (multiple modes of operation)

-

Shorter lifespan of injection system components – a combination of high pressure, poor gasoline lubricity and injector deposits (carbon build-up)

-

Susceptibility to carbon build-up on the intake valves – lack of fuel flow over the intake valves in cars without dual injection

-

Higher emissions of particulate matter – as of 2017, some GDI engines require gasoline particulate filters (GPF) to meet emission standards

-

Accelerated engine oil degradation due to oil dilution – some of the fuel sprayed inside the cylinder gets on the cylinder walls and mixes with the oil

-

Converting a GDI engine to run on LPG (liquefied petroleum gas) is more expensive than converting a PFI engine

Summary

Now you know how direct injection works and what its benefits and drawbacks are.

Personally, I’d pick a PFI engine over a GDI engine while I’m waiting for electric car batteries to become cheaper and better. I like simplicity and the cars I drive tend to be on the older side.

As far as the problem of carbon build-up is concerned, I wouldn’t worry about it as GDI engines have improved in that regard over the past few years. In the worst case, you may need to have the intake valves in your car cleaned. It may not be cheap, but it’s a one-off procedure that restores the performance of the car for a few years.

Before you leave, consider this:

One of the main drivers behind the increasing complexity of modern cars is emission standards. A lot of the problems car owners have (carbon build-up, clogged EGR valves and particulate filters, swirl flaps getting ingested by engines etc.) are directly linked to the car manufacturers’ struggle to meet emission limits.

With electric cars, the manufacturers don’t have to worry about emissions because there aren’t any. Let the power plants and energy supplier worry about emissions, and let car makers design cars that aren’t constrained by emission regulations. How’s that for a campaign slogan?

Stay tuned for an article explaining electric cars.

If you liked this article, please share it with your friends!

A superb and lucid article covering a complex subject. My wife owns a 2016 Honda FIT with the Earthdreams (TM) engine. This car has a GDI fuel injection system. At around 30,000, she had to have the valves cleaned of carbon buildup.

The ‘Check engine’ light and detectable misfires while driving were the clues. I believe that the walnut method was used to clean the valves.

Your article really clears up the mystery of why this young car had to have a major shop visit.

She is not a high-intensity driver; too many short trips at low speeds (<45mph) may have been a major contributor. The FIT did not see much high-speed/multi-hour driving at interstate speeds.

I have a 2011 CR-V, with around 120,000. NO such problems. According to the folks at CRC, this model year has a PFI injection system, which is the way to go to keep valves clean. The CR-V also does the majority of high-speed/multi-hour driving.

You have cleared up the Tale of Two Hondas mystery.

Regards,

thanks for the article, which is done in understandable words; looking for your notes about electric-cars. useful your remarks about lpg.

greetings

Very interesting article. I’m old enough to remember cars with carburetors, points, distributors,

adjustable valves and using timing lights and feeler gauges. They don’t make them the way they used to, and it’s a good thing.

I read somewhere that engines with direct injection don’t start as fast as port injected engines.

This is due because the engine needs a revolution or two for the mechanical high pressure pump to build up pressure. I don’t know if they have accumulators? My C7 Corvette isn’t an instant starter.

I’m not a fan of electric cars, but its the future..