Mercedes-Benz E-Class (W211: 2002-2009)

Reliability & common problems

This section covers the potential reliability issues that you might have with the Mercedes-Benz W211. Click on the buttons below to read more about the typical problems that fall outside the scope of routine maintenance.

Build quality issues

The W211 E-class cars manufactured in the first years after the model was released were considered to be less reliable than the ones made later. There is nothing terribly wrong with the early models but there were cases of electrical issues and problems with build quality.

This isn’t unusual. Often, newly released products have some problems. It takes a while for the manufacturers to sort out design flaws and quality issues. This is true not only for cars but many other products. A bit of an extreme example is the Samsung Galaxy Note 7 with its batteries catching fire.

Valeo radiators & transmission failure

The early W211 models, manufactured before 09.2003, might have been fitted with radiators that can cause expensive automatic transmission failures.

The transmission oil cooler in these cars is integrated with the radiator. The faulty radiators were made by Valeo and had a problem with an internal seal that was supposed to separate the coolant from the transmission oil. A failed seal would release the coolant into the transmission oil circuit. This oil/coolant mixture can ruin the transmission if not flushed quickly.

Cars with manual transmissions are not affected.

The coolant in the transmission is not a good thing and causes severe clutch surface wear, among other issues. The fix for a transmission contaminated with coolant is to:

-

replace the transmission (expensive)

-

rebuild the transmission (also expensive)

-

if the contamination was stopped quickly enough, a transmission flush and new transmission fluid may be enough (not that expensive)

The typical symptoms of a failing radiator seal are harsh gear changes and humming/droning noise during light acceleration up to 2500 RPM. Definitely look out for this when test driving a W211 E-class made before 09.2003.

The majority of the E-Class vehicles on the road today would have had the faulty radiators replaced by now. If you do buy a car with a Valeo radiator, consider having it replaced as there is still a small risk that it could fail. It’s much cheaper to replace a radiator as a precaution than it is to replace a dead transmission.

Only cars manufactured before 09.2003 are affected and newer Valeo radiators are fine.

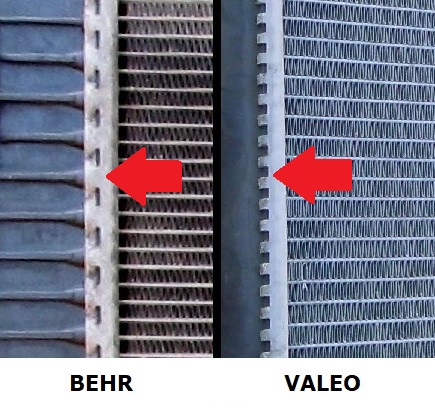

You can identify a Valeo radiator by the crimping method i.e. how the metal core is joined with the plastic sides. Here’s what it looks like:

Sensotronic Brake Control malfunction

The pre-facelift W211 models (2002-2006) were fitted with a brake-by-wire system called Sensotronic Brake Control (SBC). This system caused one of the biggest Mercedes-Benz recalls. Once the affected cars have been sorted out by the recall, the system is reasonably reliable. However, the SBC pumps on these cars have a finite lifespan, which is monitored by the car’s computer.

Once the pump reaches a fixed number of braking cycles (number of times the brake pedal is pressed) a warning light will come on. At that point, the pump needs to be replaced because it means that it has reached the end of its design life. If not replaced, the pump will eventually fail.

A new pump will cost you around £900. Reconditioned SBC pumps are also available for a smaller price.

If the SBC pump fails, a warning message is displayed on the dashboard and braking power is massively reduced – this could happen at motorway speeds. In case of pump failure, be aware that you have to apply a lot of force to the brake pedal to get the car to stop. Also, the SBC pumps occasionally fail before reaching their design lifespan.

The SBC was dropped permanently in the W211 E-Class and the C219 CLS-Class because the customers lost trust in this system after the recalls. It was replaced by traditional hydraulic brakes in the post-facelift W211 models.

In my opinion, the SBC was a failed experiment. When buying a second-hand car, it’s better to have standard hydraulic brakes that are far less complex and have been proven over decades of automotive use. They will also be much cheaper to service if anything goes wrong. Hence my recommendation to avoid pre-facelift W211 models.

Airmatic suspension

This car may be equipped with air suspension called Airmatic. The Airmatic is part of standard equipment in the E 500, E 550, E 400 CDI, E 420 CDI and AMG models. It was an optional extra in other models – this may differ between countries.

Air suspension is commonly used in trucks and buses because vehicles with air suspension can maintain correct height and level despite the load. Have you ever seen a bus tilt and soon after level out when the passengers get off at the bus stop? That’s air suspension reacting to new conditions.

The air suspension in Mercedes-Benz cars can react in the same way, and it’s capable of changing the ride height and damping stiffness. The Airmatic ride quality is indeed very good.

In an Airmatic W211, the front suspension is fitted with a pair of struts – air springs and dampers integrated into single units. In the back suspension, the air springs and dampers are separate components but the principle is still the same. Here’s how the Airmatic is different from traditional spring suspension:

Traditional suspension

-

four springs – they support the car and allow suspension movement (suspension travel)

-

four shock absorbers – they dampen the spring oscillations and prevent excessive suspension movement (bouncing)

Airmatic

-

air pump (generates air pressure for the entire system)

-

air reservoir (stores compressed air)

-

ride height sensors (they measure the ride height)

-

valve body (distributes air to the air springs)

-

two struts (shock absorber and air spring in one) in the front; two air springs and two shock absorbers in the back

-

air lines that connect all of the above

In my opinion, the Airmatic is not unreliable, but it is significantly more complex than traditional suspension.

Some people got burned by trying to fix their Airmatic suspensions at a Mercedes-Benz dealership. The prices at the dealership can be high when it comes to sorting out Airmatic issues, and the typical dealership approach is to keep replacing components until the problem is fixed, without actually trying to locate the exact failure point.

The parts can be expensive but most things, like struts or the air pump, are easy to replace. In my opinion, you will be happy with the Airmatic suspension provided that you learn how the system works, and how to diagnose problems yourself, so you don’t get ripped off when something starts leaking or stops working.

Also, be aware that if some critical components in the Airmatic fail, for example, the air pump, the car will become undrivable.

There are multiple options available on the market today that can help you save money servicing the Airmatic suspension:

-

compressor repair kits

-

aftermarket parts (Arnott has a good reputation)

-

reconditioned parts

-

coil spring conversion kits (not recommended)

When checking the Airmatic suspension, look out for the following symptoms of malfunction:

-

air compressor running too loud (worn out)

-

compressor turning on too often (air leak)

-

Airmatic fault messages when the car is cornering or braking hard

-

the car taking too long to raise from lowest position (air leak or worn out air pump)

-

cracked dust covers on the struts (any damage there will massively accelerate the wear by allowing dirt and moisture in)

-

oil leaks at the bottom of the struts (leaking shock absorbers)

-

check that the car responds quickly to manually adjusting the height with no warning messages

-

car dropping too quickly – on one corner or more than one

Check the car after it has been standing still overnight – it should not be on the ground. A little bit of pressure may escape, but the car should stay up and level.

A system in good condition should be able to hold air for a couple days easily. If it drops in a couple hours, something is worn out or there is a significant leak somewhere. If the car drops too low to drive, “Car too low” message will appear on the dashboard – it’s a bad sign.

Driving with air leaks will prematurely kill the air pump because then it has to turn on more often to replace the escaping air. If you are going to buy a car that has a leaking system, expect the air pump to be on its way out too.

W211 “Estate” – self-levelling rear air suspension

The W211 “Estate” is equipped with self-levelling, rear air suspension. You can think of it as “half of Airmatic“. Its function is to keep the rear end of the car level, regardless of the load in the boot.

The rear suspension in the W211 Estate consists of a pair of air springs and a pair of regular shock absorbers. Just like in the regular Airmatic, there is an air compressor that feeds the rear air springs. Unlike in the regular Airmatic, there are no controls for the rear air suspension in the cabin.

The rear air suspension is more expensive to service than traditional suspension but cheaper than the full Airmatic.

M271 engine – “Kompressor” and “E 200 NGT”

These engines are fitted with superchargers. The superchargers are reliable but have a finite lifespan. I estimate that they will need to be rebuilt after around 150,000 miles. The engine and other components under the bonnet will last a lot longer, so it’s very likely that the car will need to have the supercharger rebuilt or replaced at some point during its lifetime.

M271 engine – timing chain stretch

Generally, when a timing chain is used, the intention is for it to last the “lifetime” of the engine (very roughly 200k miles). Leaving it for this long in the M271 engine is very risky, in my opinion.

There have been cases of premature chain stretch in these engines. As the chain stretches, at some point it will reach the limit of what the chain tensioner can compensate for. The tensioner uses oil pressure to apply tension to the chain when the car is running. There is also a spring that applies some tensions when the engine is off and there is no oil pressure.

What happens is that when the chain is stretched too much, the spring alone cannot apply enough tension, and it becomes possible for the loose chain to jump some teeth on the timing gears. I believe this is why most of the M271 failures occur during engine start up. When the chain skips, major engine damage can occur if the valve timing goes out of sync far enough for the valves to hit the pistons.

For some reason, Mercedes-Benz decided to use a single row timing chain in the M271 engine while its predecessors, the M111 and the even older M102, had double row timing chains, which were very reliable.

The timing chain should be watched in the M271. If it starts showing any symptoms of stretch, it should be replaced. It’s difficult to estimate precisely how long the chain will last. There have been cases of chain failures at 80k miles, and there are cars that go far past 100k without any problems. In my opinion, you should treat the chain as a 100k miles service item if you want to be really safe.

You have three options:

-

Avoid the M271 engine entirely.

-

Get one that already had the chain and chain tensioner replaced. The replacement chain should be good for another 100k miles.

-

Buy the car, and plan to get the timing chain replaced at some point. The timing sprockets may need replacing as well if they are worn.

A typical symptom of a stretched timing chain is a chain rattle that lasts a couple of seconds after a cold start. In severe cases, the engine may be difficult to start as well. Usually, the “Check Engine” light won’t come on. Click here to learn more about timing chains and how to check them.

M271 engine – capillary action (oil in wiring loom)

The M271 engine is equipped with Variable Valve Timing (VVT). Mercedes-Benz employed VVT in most petrol engines from that time. The VVT system is operated using two camshaft solenoids attached to the front of the engine.

The solenoids occasionally develop minor leaks, which would normally be completely harmless. However, in the M271 the electrical plugs that connect the solenoids are pointing down…

What happens is that oil, leaking out of the camshaft solenoids, can enter the wiring harness and embark on a great journey through the wiring to the oxygen sensor, mass airflow sensor (MAF) and finally the Electronic Control Unit (ECU).

A pretty ridiculous problem, don’t you think?

This is possible because of capillary action – the ability of a liquid (engine oil in this case) to flow through narrow spaces (wire strands) without the assistance of any external forces. If this sounds astonishing, think about how difficult it is to predict such behaviour. Don’t be too hard on Mercedes-Benz engineers.

If oil gets into the wiring harness, most of it will end up at the oxygen sensor, which usually fails first. If the oil isn’t stopped, it may reach the MAF, and lastly the ECU.

The solution is simple – fix any leaks from the camshaft solenoids, and fit short extension cables (pigtails) so that the capillary action is interrupted at the pigtail. With the pigtails fitted, the oil cannot travel further to the actual wiring loom, which is plugged into the pigtail.

If you’re going to buy a car with the M271, I advise you to check the plugs on the cam solenoids for any oil. They are on the front of the engine and easy to get to. If the oil has already contaminated the wiring loom, then it will need to be cleaned or replaced.

Once you buy the car, fitting the extensions is cheap insurance – much cheaper than replacing the oxygen sensor, MAF, or the ECU. Please note that many cars will have the extensions already fitted – there was a service campaign regarding this issue.

M272 & M273 engines – soft balance shaft gears

The M272 V6 engines are equipped with a balance shaft. A balance shaft is an eccentric weighted shaft, which is used to eliminate engine vibration. It is driven by the timing chain as it needs to in sync with the engine pistons. A balance shaft is needed to make a V6 engine smooth because they are inherently unbalanced.

The M272 engines, that were manufactured between 2004 and 2008, are fitted with balance shaft gears and idler gears that can wear out prematurely. The M273 engines don’t have balance shafts, but they still have idler gears where the balance shafts would be.

These gears may be defective too. As these gears wear, the engine timing is altered due to increased slack in the timing chain.

The first indication of a problem is the “Check Engine” light and P0017 or P0016 error codes. As the sprockets continue to wear, the engine will develop a rattle from the loose timing chain. All the while, more and more metal is being ground away from the gears. If not fixed, one of the gears may fail eventually and take the engine out (valves hitting the pistons).

It is a problem that you should not ignore. The fix is to replace the gears with updated ones, which don’t wear out. It is very labour intensive, which makes it a very expensive repair.

Not all M272 and M273 engines made before 2009 are affected. Engine serial numbers below have updated gears, which are free from the problem:

-

M272 engines with serial numbers higher than 2729 . . 30 468993

-

M273 engines with serial numbers higher than 2739 . . 30 088611

Some engines seem to last despite having the unlucky gears, but I would not take the risk. In my opinion, affected engines are fine only as long as there is proof that the faulty gears (along with a number of other parts) have been replaced, and the engine is running well after the repair.

M272 & M273 engines – variable intake manifold

The intake manifold in these engines is very complex. It’s called a Variable (Length) Intake Manifold (VIM or VLIM), and it consists of three vacuum actuators, multiple levers, tumble flaps and valves that adjust the length of the intake tract.

It’s not a very reliable design with lots of plastic parts that can fail. When there’s a problem with the intake manifold, the engine performance is reduced (increased fuel consumption, loss of power, poor idle), and the “Check Engine” light may come on.

The typical cause of failure is increased friction in the mechanism from the accumulation of oil and carbon deposits in the intake manifold. Additionally, over the years the plastic parts in the mechanism become weaker and more brittle.

A couple of years ago you had to buy an entire manifold assembly to fix this problem (£800 at the dealership). Luckily, there are repair kits available on the market these days, which makes this a much smaller issue.

If you are curious how carbon deposits and oil appear in the engine intake manifold – they come from the Exhaust Recirculation Valve (EGR) and Crankcase Ventilation System (CVS). These are standard systems used on virtually all road cars.

M156 engine – head bolt corrosion (E 63 AMG)

There have been cases of head bolt failures due to corrosion in the M156 engines. The head bolts are the fasteners that hold the cylinder heads in place. They are in constant tension to create a seal between the cylinder head and the engine block (engine block – head gasket – cylinder head).

When the bolts start corroding, the clamping force may be reduced, which could allow coolant to leak into the combustion chamber or mix with the engine oil. A typical symptom is dropping coolant level while the oil level is rising. If left untreated, the oil/coolant mix will eventually turn to sludge.

Coolant entering the combustion chamber can also cause increased smoking and a rough idle.

If any of the bolts holding the cylinder heads break off, a severe head gasket leak may appear. If the leak is large enough, the coolant entering the combustion chamber has the potential to hydrolock the engine.

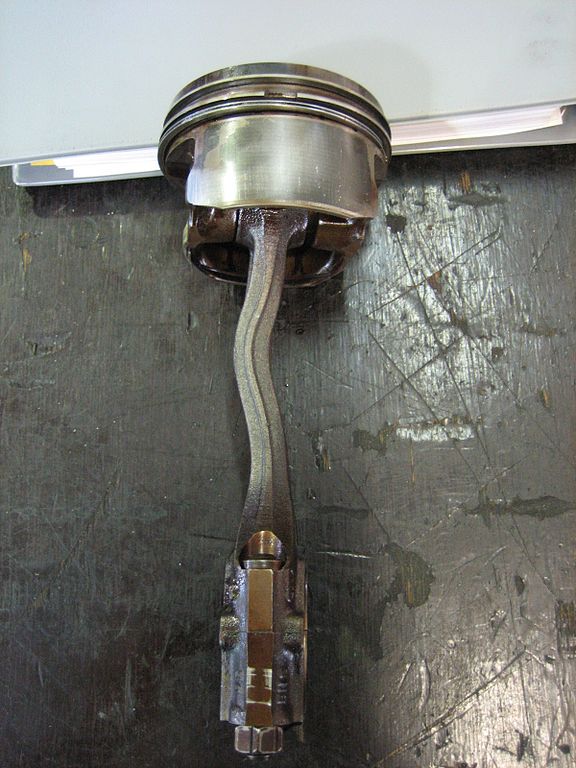

Hydrolock is a situation when the piston tries to compress the incompressible liquid. The liquid is not going to give in but something in the engine will – usually the connecting rods. To illustrate, here’s a photograph of a bent connecting rod after hydrolock (not from a Mercedes-Benz):

Photo by MichaelXXLF; Source: Wikipedia; License: CC BY-SA 3.0

Mechanical engine damage is the worst case scenario, usually, the cars start losing coolant before failing like this.

The head bolts were eventually updated by AMG around 06.2010. All engines made before this date are affected – engines with serial numbers beyond 569xx 60 060658 have the updated bolts. Unfortunately, the production of the E 63 AMG stopped before AMG fixed the head bolt issue.

I recommend avoiding the E 63 AMG unless you can get a warranty that covers potential engine meltdown or replace the head bolts preemptively. The percentage of engines that fail is small, as I see it, but it’s not worth the risk to me.

M156 engine – camshaft wear (E 63 AMG)

As I see it, another weak point of the M156 engines are the camshafts, which are susceptible to premature wear. A typical symptom of a worn camshaft is a ticking noise, initially only when the car is cold started. Over time, it becomes more persistent as the wear progresses.

I believe that this is caused by a combination of too soft camshaft lobes and too hard cam followers. The camshaft lobes are quite sharp (small nose radius), which may contribute to the problem. It’s not only the camshafts that can wear. Once a camshaft is scored and loses its profile, the cam followers can wear too – in severe cases to the point of breaking a hole in the centre.

If you decide to get one of these cars, listen for a ticking noise for the first couple seconds after a cold start. It’s the same procedure as checking for timing chain issues, so look out for any chain rattle too. If you hear a ticking noise, it’s likely the camshaft. If you can hear a rattle which disappears after a couple seconds, it’s most likely the timing chain. Both types of noises are a bad sign.

Also, regular oil changes are very important for camshaft life. You should avoid cars with incomplete service history.

Here’s what a worn-out camshaft in the M156 engine looks like:

OM642 engine – oil cooler leaks

The pre-2010 OM642 engines were notorious for leaking oil from the oil cooler seals. The original seals (orange colour) weren’t able to withstand the heat and developed leaks. Updated seals (purple colour) were introduced in 2010.

There was a recall for this issue, so hopefully, most vehicles would have had the seals replaced by now. Before buying one, check if the seals have indeed been replaced and inspect the car for oil leaks.

The seals are cheap. However, their replacement is expensive as the fuel injection system and intake manifold need to be disassembled to get to the oil cooler. The oil cooler sits on top of the engine, between the cylinder banks, underneath the intake manifold. The symptoms of a leaking oil cooler are dropping oil level and oil underneath the vehicle after a longer stand still.

OM642 engine – swirl flap motor failure

There have been cases of swirl flap motor failures in the OM642 engines due to contamination with engine oil. The swirl flap motor is located below the turbocharger and the turbo intake tends to develop leaks in this engine. The oil leaking out from the air intake may get onto the swirl flap motor and cause it to fail.

When the swirl flap motor fails, it puts the car in limp home mode along with turning the “Check Engine” light on. The air vented from the crankcase through the PCV system contains oil vapours. The PCV breather pipe is connected to the air intake before the turbocharger – that’s how engine oil gets into the intake manifold.

Replacing the swirl flap motor is not as painful as replacing the oil cooler seals, but there is still a lot of parts in the way, and the motor itself is not that cheap.

For this reason, people came up with a way to disable the swirl flap motor using a simple resistor to trick the car’s ECU into thinking that the motor is working. This solution is cheaper than replacing the faulty motor at the cost of more pollution.

The swirl flaps are not essential for the engine to run – they are there to improve emissions and disabling them has a minimal impact on engine performance. Keep in mind that disabling emissions controlling equipment is considered illegal in most countries.

Black Death (all diesel engines)

The first two generations of CDI diesel engines may develop leaks from the fuel injector seals (copper washers). When a leak occurs, the gases and the diesel fuel from the combustion chamber can escape and cover the area around the leaking injector with burnt, hard, tar-like substance.

“Black death” is a dramatic name for something relatively inexpensive to fix, provided that you catch it early. Any leaks should be visible once the plastic engine cover is removed.

If there was a leak, you will see a black mess on top of the engine. You may also smell diesel fuel inside the car when the engine is running. If the leak is large enough, the engine may sound like a steam locomotive due to gases escaping from the combustion chamber.

If left untreated, it can become very expensive to fix – injectors seized in the cylinder head, damaged injectors seats and massive carbon build-up to clean.

OM628 engine – timing chain problems

There have been cases of people having problems with the timing chain stretch in the OM628 engines. It’s not a common engine so there isn’t much information out there, but apparently, the chain tensioner and one of the slide rails were updated in 2002 to prevent the chain from skipping teeth (updated tensioner part number is A6280500311, while the original was A6280500011).

The W211 appeared in 2002 so it should already have the updated parts, at least from 2003. I don’t think the problems with the early OM628 engines are a deal breaker, just be careful when buying a car with the OM628 engine – pay extra attention to any unwanted chain noises and avoid high mileage cars. The first symptom of any chain or chain tensioner problems is usually a timing chain rattle after a cold start.

Summary of problems & additional information

-

Corrosion was a big problem with the W210 E-Class. Luckily for us, Mercedes-Benz got it right with the W211 E-Class. From 2003, the W211 has a galvanized body and much better corrosion protection than earlier Mercedes-Benz cars.

-

If you like the W211 E-class, have a look at the Chrysler 300C. It is derived from the W211 and shares parts with other Mercedes-Benz cars. It never had the SBC nor the Airmatic. The diesel-powered model uses the Mercedes-Benz OM642 engine.

-

Avoid the pre-facelift W211 E-Class cars (2002-2006) because of the SBC. Also, keep in mind that the W211 was galvanized since 2003.

-

A car with the Airmatic suspension will be significantly more expensive to service than a car with traditional suspension. Expect to do some maintenance work between 100k and 150k miles on an Airmatic car – it could be an air leak somewhere, a new air pump or a pair of struts. In my opinion, the Airmatic is not unreliable, just a lot more complex than traditional suspension.

-

All W211 engines are fitted with timing chains, which normally don’t have a specified replacement interval. The timing chains in the W211 are generally reliable, with some exceptions, but they will not last forever. Read more about timing chains.

-

Watch out for balance shaft and idler gear issues in the M272 and M273 engines. The balance shaft horror story and the overly complex variable intake manifold mechanisms are the only real issues with these engines. Once fixed, they are not bad units. Unfortunately, Mercedes-Benz improved the balance shaft gears only in 2008. If you are going to buy a W211 with the M272 or M273 engines, be very careful not to buy one with worn gears. Look for a car that had them already replaced or one with updated gears – check engine serial number.

-

Look out for timing chain stretch in the M271 engine, and be careful when buying a car with the OM628 diesel engine.

-

The V6 M112 and V8 M113 engines – Mercedes-Benz got both of them right. They are closely related to each other and both are reliable. Unfortunately, they are only available in the pre-facelift W211 models that have the SBC.

-

The M156 was the first engine designed fully by AMG and not based on a Mercedes-Benz engine. Despite having excellent performance and winning multiple awards, this engine has its problems. I recommend avoiding the E 63 AMG unless you are planning to do something about the head bolts that may corrode.

-

As for potential camshaft wear in the M156 engines, the safest thing to do would be to remove the valve covers and inspect the camshaft for wear before buying a second-hand E 63 AMG. Many of these engines can reach a relatively high mileage without problems. If you are certain that the camshafts are in good shape in the car you are planning to buy, you should not have any issues for quite a while, provided that you maintain the engine well.

-

Click here for an article that might help you decide if a modern diesel engine, like the Mercedes-Benz CDI, is the right choice for you. The diesel engines in the W211 may have a diesel particulate filter (DPF). Before buying a particular car, you can check if it has a DPF by decoding the Vehicle Identification Number (VIN). The DPF is marked as option 474.

-

The OM642 V6 diesel engine may suffer from oil cooler leaks if the seals haven’t been replaced yet. All diesel engine in the W211 may suffer from injector seal leaks (“Black Death“). Other than that, the things that could go wrong with the OM642 and other CDI engines are typical for most Common Rail diesels.

-

Please be aware that Mercedes-Benz is a manufacturer of high-performance luxury cars. High performance usually goes hand in hand with increased complexity. When things go wrong, you can expect the service costs to be above average.

Mercedes-Benz W211 specifications

This section contains Mercedes-Benz W211 specifications. You will also find technical information regarding the engines used in these cars. Press the buttons below to display the specs and engine technical details.

Petrol engines – specs & performance figures

| Model | Engine | Displacement | Power | Torque | Comments |

|---|---|---|---|---|---|

| E 200 Kompressor | M271 | 1796 cm³ / 109.6 cu in | 163 PS / 120 kW | 240 Nm / 177 lbf⋅ft | Until 2006, supercharged |

| E 200 Kompressor | M271 | 1796 cm³ / 109.6 cu in | 184 PS / 135 kW | 250 Nm / 184 lbf⋅ft | From 2006, supercharged |

| E 200 NGT | M271 | 1796 cm³ / 109.6 cu in | 163 PS / 120 kW | 240 Nm / 177 lbf⋅ft | From 2004, supercharged |

| E 230 | M272 | 2496 cm³ / 152.3 cu in | 204 PS / 150 kW | 245 Nm / 181 lbf⋅ft | from 2006 |

| E 240 | M112 | 2597 cm³ / 158.5 cu in | 177 PS / 130 kW | 240 Nm / 177 lbf⋅ft | Until 2005 |

| E 280 | M272 | 2996 cm³ / 182.8 cu in | 231 PS / 170 kW | 300 Nm / 221 lbf⋅ft | From 2005 |

| E 320 | M112 | 3199 cm³ / 195.2 cu in | 224 PS / 165 kW | 315 Nm / 232 lbf⋅ft | Until 2005 |

| E 350 | M272 | 3498 cm³ / 213.5 cu in | 272 PS / 200 kW | 350 Nm / 258 lbf⋅ft | From 2004 |

| E 500 | M113 | 4966 cm³ / 303.0 cu in | 306 PS / 225 kW | 460 Nm / 339 lbf⋅ft | Until 2006 |

| E 500 | M273 | 5461 cm³ / 333.3 cu in | 388 PS / 285 kW | 530 Nm / 391 lbf⋅ft | From 2006, "E 550" in the US |

| E 55 AMG | M113 | 5439 cm³ / 331.9 cu in | 476 PS / 350 kW | 700 Nm / 516 lbf⋅ft | 2003-2006, supercharged |

| E 63 AMG | M156 | 6208 cm³ / 378.8 cu in | 514 PS / 378 kW | 630 Nm / 465 lbf⋅ft | From 2006 |

Diesel engines – specs & performance figures

| Model | Engine | Displacement | Power | Torque | Comments |

|---|---|---|---|---|---|

| E 200 CDI | OM646 | 2148 cm³ / 131.1 cu in | 102 PS / 75 kW | 235 Nm / 173 lbf⋅ft | Taxi |

| E 200 CDI | OM646 | 2148 cm³ / 131.1 cu in | 122 PS / 90 kW | 270 Nm / 199 lbf⋅ft | Until 2006 |

| E 200 CDI | OM646 | 2148 cm³ / 131.1 cu in | 136 PS / 100 kW | 340 Nm / 251 lbf⋅ft | From 2006 |

| E 220 CDI | OM646 | 2148 cm³ / 131.1 cu in | 150 PS / 110 kW | 340 Nm / 251 lbf⋅ft | Until 2006 |

| E 220 CDI | OM646 | 2148 cm³ / 131.1 cu in | 170 PS / 125 kW | 400 Nm / 295 lbf⋅ft | From 2006 |

| E 270 CDI | OM647 | 2685 cm³ / 163.8 cu in | 177 PS / 133 kW | 400 Nm / 295 lbf⋅ft (manual) or 425 Nm / 313 lbf⋅ft (automatic) | Until 2005 |

| E 280 CDI | OM648 | 3222 cm³ / 196.6 cu in | 177 PS / 133 kW | 425 Nm / 313 lbf⋅ft | 2004-2005 |

| E 280 CDI | OM642 | 2987 cm³ / 182.3 cu in | 190 PS / 140 kW | 400 Nm / 295 lbf⋅ft (manual) or 440 Nm / 324 lbf⋅ft (automatic) | 2005-2009 |

| E 320 CDI | OM648 | 3222 cm³ / 196.6 cu in | 204 PS / 150 kW | 500 Nm / 369 lbf⋅ft | Until 2005 |

| E 320 CDI | OM642 | 2987 cm³ / 128.3 cu in | 224 PS / 165 kW | 510 Nm / 376 lbf⋅ft or 540 Nm / 398 lbf⋅ft | From 2005 |

| E 400 CDI | OM628 | 3996 cm³ / 243.9 cu in | 260 PS / 191 kW | 560 Nm / 413 lbf⋅ft | Until 2005 |

| E 420 CDI | OM629 | 3996 cm³ / 243.9 cu in | 314 PS / 231 kW | 730 Nm / 538 lbf⋅ft | From 2005 |

Petrol engines – technical details

| Engine | Engine config. | Forced induction | Valve timing | Fuel delivery | DMF | Inlet flaps |

|---|---|---|---|---|---|---|

| M271 | Inline-4, 16 valves | Supercharged | Timing chain, DOHC, VVT | Port injection (EFI) | Yes | No |

| M112 | V6, 18 valves | No | Timing chain, SOHC | Port injection (EFI) | Yes | No |

| M272 | V6, 24 valves | No | Timing chain, DOHC, VVT | Port injection (EFI) | Yes | Yes |

| M113 | V8, 24 valves | Naturally aspirated or supercharged (AMG) | Timing chain, SOHC | Port injection (EFI) | Auto. trans only | No |

| M273 | V8, 32 valves | No | Timing chain, DOHC, VVT | Port injection (EFI) | Auto. trans only | Yes |

| M156 | V8, 32 valves | No | Timing chain, DOHC, VVT | Port injection (EFI) | Auto. trans only | No |

| Legend: | SOHC - Single Overhead Camshaft DOHC - Double Overhead Camshaft VVT - Variable Valve Timing EFI - Electronic Fuel Injection DMF - Dual-mass Flywheel (does not apply to auto. transmissions with torque converters) |

|||||

Diesel engines – technical details

| Engine | Engine config. | Forced induction | Valve timing | Injection system | DMF | DPF | Swirl flaps |

|---|---|---|---|---|---|---|---|

| OM646 | Inline-4, 16 valves | Turbo | Timing chain, DOHC | Common Rail | Yes | Some engines | Yes |

| OM647 | Inline-5, 20 valves | Turbo | Timing chain, DOHC | Common Rail | Yes | No (optional) | Yes |

| OM648 | Inline-6, 24 valves | Turbo | Timing chain, DOHC | Common Rail | Auto trans. only | No (optional) | Yes |

| OM642 | V6, 24 valves | Turbo | Timing chain, DOHC | Common Rail | Yes | Yes | Yes |

| OM628 | V8, 32 valves | Parallel twin turbo | Timing chain, DOHC | Common Rail | Auto trans. only | No | Yes |

| OM629 | V8, 32 valves | Parallel twin turbo | Timing chain, DOHC | Common Rail | Auto trans. only | Yes | Yes |

| Legend: | DOHC - Double Overhead Camshaft DPF - Diesel Particulate Filter DMF - Dual-mass Flywheel (does not apply to auto. transmissions with torque converters) |

||||||

Mercedes-Benz W211 wheel sizes

Press the button below to see the original equipment manufactuer (OEM) rim & tyres sizes for the Mercedes-Benz W211. These are the original wheel sizes that were fitted by the manufacturer.

| Tyres | Rims | Centre Bore | Bolt Pattern | Comments |

|---|---|---|---|---|

| 205/60 R16 | 7Jx16 ET33 | 66.6mm | 5x112 | |

| 225/55 R16 | 7.5Jx16 ET42 or 8Jx16 ET36 | 66.6mm | 5x112 | |

| 245/45 R17 | 8Jx17 ET38 or 8.5Jx17 ET38 | 66.6mm | 5x112 | |

| 245/40 R18 | 8Jx18 ET30 | 66.6mm | 5x112 | |

| 245/40 R18 front & 265/35 R18 rear | 8Jx18 ET30 front & 9Jx18 ET39 rear | 66.6mm | 5x112 | E 55 AMG, staggered setup |

| 245/40 R18 front & 265/35 R18 rear | 8.5Jx18 ET38 front & 9Jx18 ET39 rear | 66.6mm | 5x112 | E 63 AMG, staggered setup |

Share this page: